Vacuum Melt Spinning Furnace with Precision Temperature

It is a lab-scale vacuum melt spinning system for preparing amorphous metallic ribbons. In this technique, metal ingots (<50g) are melted via induction heating method and then propelled by over-pressurizing the crucible.

Product Description

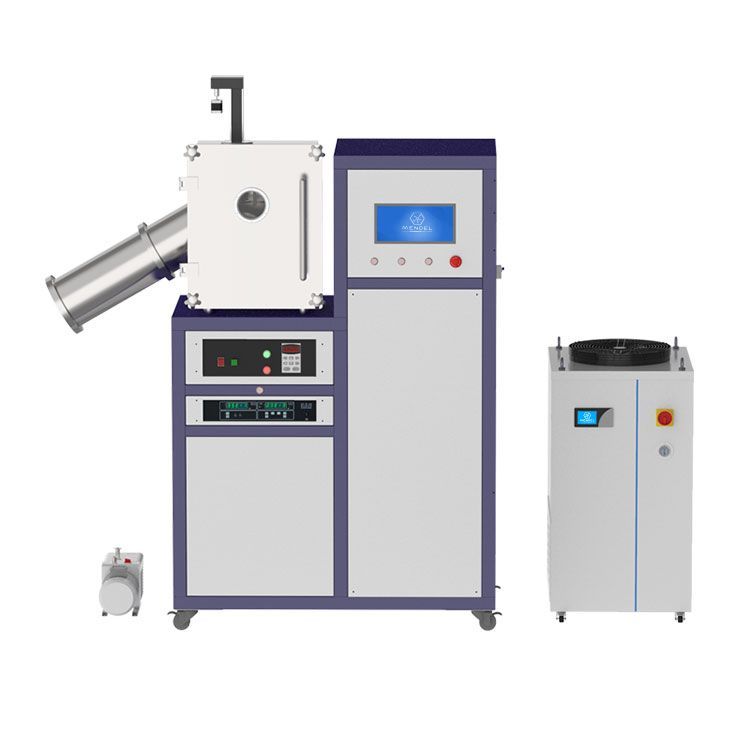

Introducing the BTF-500, a laboratory-scale vacuum melt spinning system meticulously designed for the preparation of amorphous metallic ribbons. This innovative system employs an induction heating method to melt metal ingots (<50g), propelling them through over-pressurizing the crucible. The BTF-500 incorporates a range of technical parameters and features aimed at optimizing its functionality.

The system is comprised of a robust stainless steel vacuum chamber, an efficient vacuum system, an induction heating system, a sturdy rack system, and a discharging tubular collector. At its core, a copper roller with a linear speed ranging from 5 to 60 meters per second plays a pivotal role, allowing for the melting of metallic samples in batches ranging from 5 to 50 grams. Power supply requirements specify AC380V, three-phase, with a maximum power capacity of 15 kilowatts, necessitating a 60-ampere air switch for optimal operation. The vacuum chamber, measuring Φ 500mm in diameter and 400mm in length, features a hinged cavity door with a quartz observation window for real-time monitoring.

Equipped with a molecular pump system, the BTF-500 achieves a commendable vacuum level of 5 x 10E-5 Torr within 20 minutes and a limiting vacuum of 10E-7 Torr after baking. The induction heater, delivering 15kW of heating power within a frequency range of 30 to 80 kilohertz, accommodates melting sample quantities ranging from 10 to 50 grams, depending on the material. The system integrates an accurate temperature control system, utilizing a B-type thermocouple, and allows for the programming of 30 temperature rise and fall procedures with a temperature control accuracy of ±2℃.

Flexibility is a key feature, with the option to use either quartz or BN crucibles based on customer requirements. The spinning wheel, comprising a standard copper roller with cooling features, achieves a linear speed of 5 to 60 meters per second. For enhanced capabilities, an optional water-cooled copper roller is available, accommodating sample handling capacities of up to 500 grams. Additional accessories, including casting accessories (casting and spray casting) and a customized water cooling system for the casting copper mold, can be acquired based on specific needs.

The system's dimensions of 2000mm in length, 1100mm in width, and 1800mm in height, coupled with a weight of approximately 800 kilograms, ensure a robust and stable platform. Notably, the BTF-500 holds CE certification, attesting to its adherence to stringent safety and quality standards. This system stands as a sophisticated and certified solution for advanced laboratory research in the field of amorphous metallic ribbons.

Disclaimer: The information presented on this website, including product images, product descriptions, and technical parameters, serves as a reference guide. Please note that due to potential delays in updates, discrepancies may exist between the content displayed here and the current product status. We encourage you to reach out to our dedicated sales team to verify the most up-to-date details. It is important to understand that the information provided on this site does not constitute a formal offer or commitment, and our company reserves the right to periodically enhance and amend website information without prior notice. We appreciate your understanding in this regard.