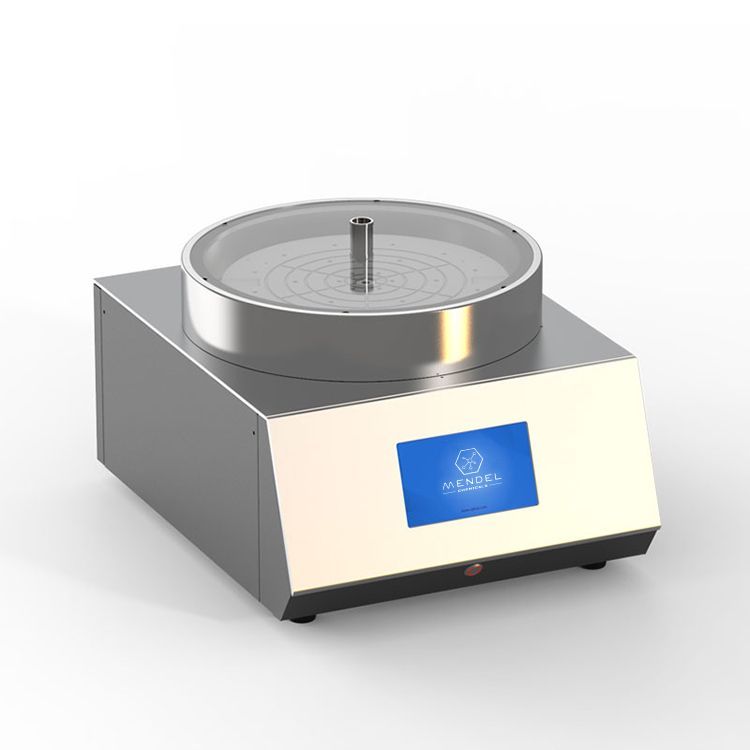

Stainless steel chamber spin coater for wafers up to 12"

The SPC12-C spin coater features a vacuum chuck for efficient and rapid sol-gel coating on wafers with a diameter of up to 12 inches. It employs a sophisticated precision motor capable of achieving a maximum speed of 5000rpm, ensuring consistent and uniform film deposition. Moreover, this instrument is controlled via a user-friendly touch screen interface, enabling presetting of coating curves, thereby streamlining the entire process.

Product Description

The spin coater is versatile in its applications, capable of applying liquid or colloidal materials onto various substrates, including silicon wafers, crystals, quartz, ceramics, and more, to create thin films. Its primary uses encompass photoresist spin coating, the preparation of biological media, and the production of polymer films using the sol-gel method, among other applications.

The spin coater operates on an AC220V, 50Hz power supply and is available in two chamber material options: PP or stainless steel with a transparent acrylic upper cover. It accommodates substrates with a diameter of up to 12 inches (approximately 300mm) and offers variable spin speeds ranging from 0 to 5000rpm, with adjustable acceleration settings between 100 and 5000rpm/s and a precise 1rpm speed resolution. The coater supports single-step durations of up to 3000 seconds and is operated through an intuitive 7-inch HD LCD touch screen. Dispensing is done manually. The coater allows for the creation of coating curves, with each curve comprising 5 segments, and the capacity to store a total of 5 different curves. It includes a vacuum chuck for secure substrate placement and utilizes an oil-less pump for vacuum operations, offering a pumping speed of 50 L/min. The total weight of the equipment is approximately 40kg.

Disclaimer: The information presented on this website, including product images, product descriptions, and technical parameters, serves as a reference guide. Please note that due to potential delays in updates, discrepancies may exist between the content displayed here and the current product status. We encourage you to reach out to our dedicated sales team to verify the most up-to-date details. It is important to understand that the information provided on this site does not constitute a formal offer or commitment, and our company reserves the right to periodically enhance and amend website information without prior notice. We appreciate your understanding in this regard.