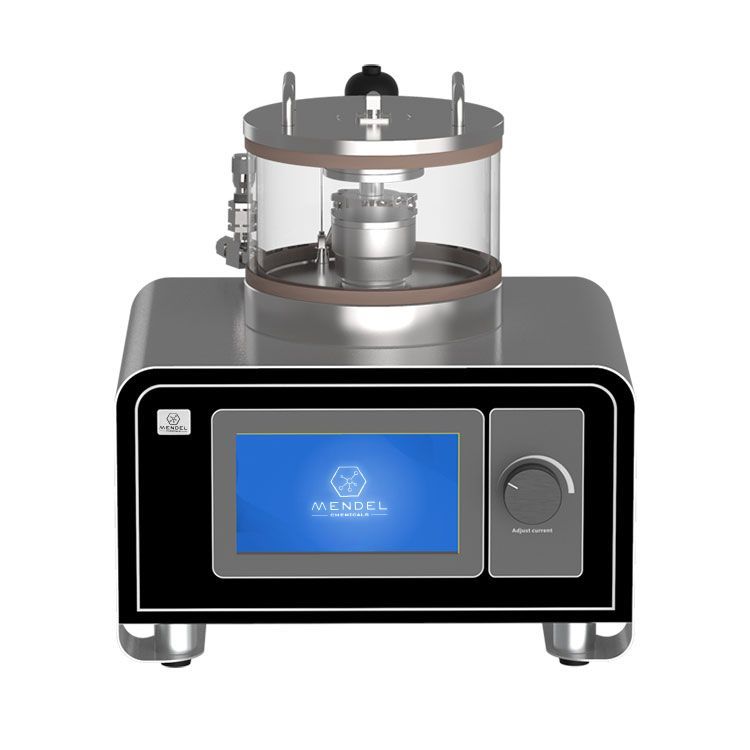

Small plasma sputtering coater PSP180G-1TA

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

Product Description

This small plasma sputtering coater uses PLC control system, all touch screen operation, easy to learn and use. The equipment is small in size and beautiful in appearance, making it the best choice for laboratory coating experiments. The technical parameters of the Small Plasma Sputtering Coater, identified as PSP180G-1TA, are as follows: This coater is equipped with a sample stage featuring a diameter of φ60mm, which is height-adjustable for flexibility in sample positioning. It utilizes a single 2"x1 DC sputtering head for material deposition and is constructed with a chamber made of high-purity quartz. The chamber itself has dimensions of φ180mm x 100mm, providing ample space for coating processes. For vacuum operations, the coater is equipped with a reliable rotary vane pump, capable of achieving an ultimate vacuum level of 1.0E-1Pa. The vacuum interface is established through a KF16 vacuum flange, while gas inlet is facilitated by a φ8 quick connector. The power supply for the coater is AC 220V, 50Hz, with a total power consumption of 1.5KW. These specifications make the PSP180G-1TA a suitable choice for various plasma sputtering applications, offering precise and controlled coating capabilities within its compact chamber.