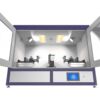

Nano fiber electrospinning system with double spinning and yarning function

Nano fiber electrospinning system with double spinning and yarning function is known as one of the most efficient, convenient methods to produce fibers of a nanometric scale. These nanometric fibers reveal several remarkable characteristics such as a large surface area to the volume ratio, high porosity, flexibility in surface functionality, and superior mechanical performance.

Product Description

The Nano Fiber Double Spinning & Yarning System emerges as an advanced solution for the efficient production of nanoscale fibers, unlocking a myriad of applications across diverse fields. Renowned for its exceptional properties, including high surface area-to-volume ratio, porosity, flexibility, and mechanical strength, nanofibers play a pivotal role in industries such as filtration, medical devices, multifunctional membranes, and military systems. This electrospinning system is thoughtfully equipped with features to optimize functionality and ensure user safety.

Temperature regulation is a key highlight, with the system capable of maintaining a controlled environment up to 45℃ using a powerful 1000-watt coil heater. To address static concerns, a Residual Charge Discharge Stick is integrated into the chamber. Safety features include a door-activated switch that disables the high-voltage power supply when the door is open, ensuring secure operation. Enhanced visibility is facilitated through LED cabin lighting and backlighting for observing the electrospinning process. An exhaust fan serves a dual purpose, aiding solvent vaporization and post-spinning equipment cooling. An emergency stop feature on the control panel provides a swift response in case of unforeseen circumstances.

The system's robust design incorporates a granite surface with graduation scales, promoting repeatability by marking the positions of syringe pumps, the target, and rim rotator. User-friendly software enables precise control of parameters, fostering PC interfacing for regulating the rotating speed of the collector, spin duration, spool speeds, and syringe pump flow rate. Various target options, including rotating mandrel targets, a stationary target, reciprocating XY target, metal funnel collector, and rim rotator, offer versatility in fiber fabrication. The coaxial spinneret enables the production of diverse nanofiber structures, further expanding the system's capabilities.

Technical parameters contribute to the system's efficiency and versatility. The high-voltage power supply, NFES-DE model, allows precise control over output voltage and current, ranging from -15kV to +15kV. An independently controlled dual-channel syringe pump supports custom fiber fabrication, while a metal funnel collector, rotating at adjustable speeds, forms twisted nanofiber yarns. Rotating mandrels offer versatility in obtaining aligned continuous mesh nanofibers, and a Y plate collector & stationary target ensures uniform fiber deposition.

Ensuring safety and environmental control, a fume hood (FH-03 model) features transparent windows, temperature control, and an exhaust fan. Additional accessories and optional features, such as a UV curing lamp for fiber curing, contribute to the system's comprehensive functionality. The Nano Fiber Electrospinning System is meticulously designed to meet diverse nanofiber production needs, prioritizing precision and safety.

Disclaimer: The information presented on this website, including product images, product descriptions, and technical parameters, serves as a reference guide. Please note that due to potential delays in updates, discrepancies may exist between the content displayed here and the current product status. We encourage you to reach out to our dedicated sales team to verify the most up-to-date details. It is important to understand that the information provided on this site does not constitute a formal offer or commitment, and our company reserves the right to periodically enhance and amend website information without prior notice. We appreciate your understanding in this regard.