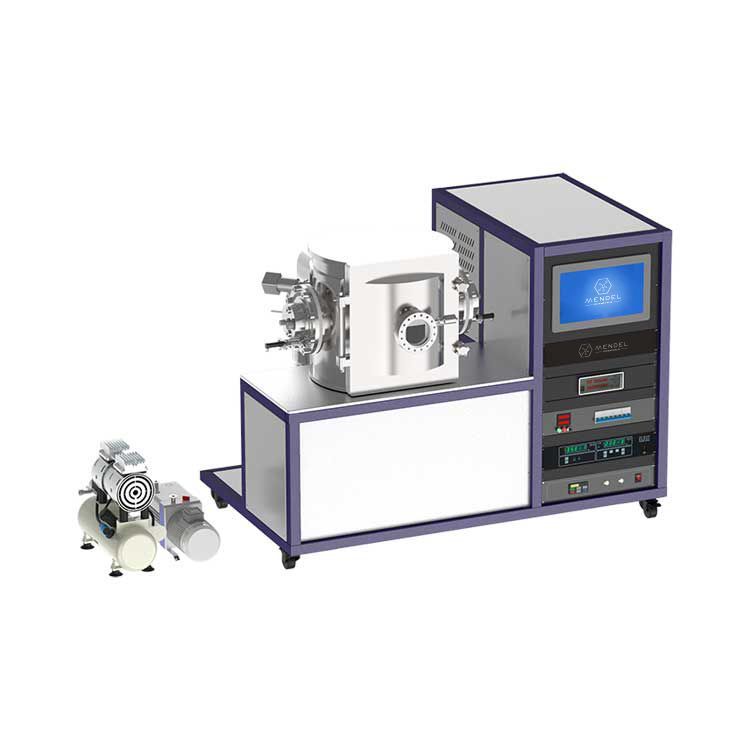

Multi arc ion coating equipment

Multi-arc ion plating is the use of gas discharge or partial ionization of evaporated substances, while gas ions or particles of evaporated substances are bombarded, the evaporated substances or reactants are deposited on the substrate. Ion plating combines the glow discharge, plasma technology and vacuum evaporation organically, which not only significantly improves the film quality, but also expands the application range of the film. It has the advantages of fast evaporation rate, strong film adhesion, good diffraction, and extensive film materials. It is very suitable for plating hard protective film such as TiN. At the same time, because it can change the color of the film by controlling the atmosphere, and the film is firmly combined with the substrate, it can also be used to make decorative films of various colors.

Product Description

The multi-arc ion coating equipment, represented by the model MIOP500S-2TA, boasts a set of advanced features designed to enhance efficiency and user safety. Equipped with two multi-arc targets strategically positioned on both sides of the φ500mm diameter and 490mm height water-cooled stainless steel vacuum chamber, this equipment leverages a planetary sample stage to optimize coating efficiency and improve overall coating effects. The integrated design emphasizes user safety by separating the chamber and electric control components, ensuring the segregation of water and electricity.

The chamber's thoughtful design includes a front door with a φ100mm quartz observation window, providing enhanced visibility during operations. Incorporating two sets of built-in infrared heating lamps for baking and degassing, the chamber supports precise monitoring through multiple reserved CF interfaces for a multi-channel film thickness meter. The gas system is configured with mass flow meters for Ar and N2 gases, customizable within the ranges of 0 to 200sccm. The power supply requirement is AC 220V, 50Hz, with a capacity of 10kW. Control is facilitated through a 15" touch screen configuration with dedicated control software.

The multi-arc target system features two sets of 3-inch targets that can be flexibly installed on the chamber's sides. The working current is adjustable within the range of 0 to 150A, and the target thickness is maintained at a minimum of 20mm, standardized at 50mm. The sample stage incorporates a planetary hanger with six hanging points on each of the six hangers, enabling rotation speeds from 1 to 20rpm for versatile sample processing.

The vacuum system, model GZK103-A, integrates a turbo molecular pump with a capacity of 600L/S for rapid evacuation and a double-stage rotary vane pump with a capacity of 1.1L/S. Achieving an ultimate vacuum of 5×10E-4Pa, the system incorporates extraction and exhaust interfaces of KF40 and KF16, respectively. Vacuum conditions within the chamber are precisely controlled through a composite vacuum gauge, ensuring accurate and reliable measurements. This comprehensive set of features positions the multi-arc ion coating equipment as an advanced and user-friendly solution for various coating applications.

Disclaimer: The information presented on this website, including product images, product descriptions, and technical parameters, serves as a reference guide. Please note that due to potential delays in updates, discrepancies may exist between the content displayed here and the current product status. We encourage you to reach out to our dedicated sales team to verify the most up-to-date details. It is important to understand that the information provided on this site does not constitute a formal offer or commitment, and our company reserves the right to periodically enhance and amend website information without prior notice. We appreciate your understanding in this regard.