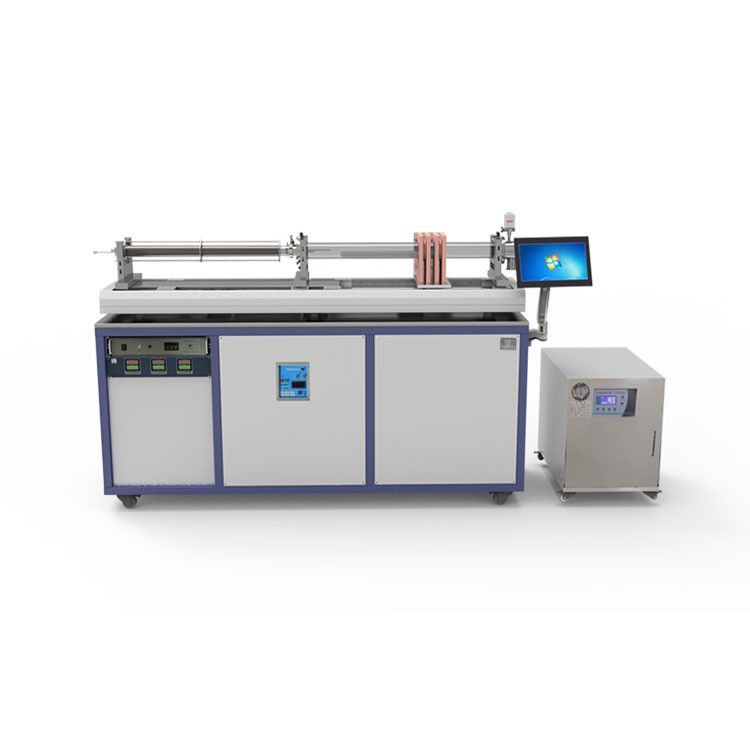

Induction type electromagnetic shielding area purification furnace

The purification furnace is a method of fire refining that deeply purifies metals, metal compounds, or alters the distribution of impurities in metal ingots. In its essence, it creates a narrow melting zone by locally heating a long and narrow metal ingot, causing it to move slowly along the ingot in a specific direction. The process utilizes the difference in equilibrium concentration of impurities between the solid and liquid phases to segregate impurities into either phase. Repeated operations can redistribute impurities to one or both ends of the ingot, allowing for the removal of high impurity content and the attainment of high-purity metal.

Product Description

Currently, about 1/3 of the elements and hundreds of inorganic and organic compounds can be purified to very high purity through zone smelting. The purification process requires a slow speed of the melting zone, typically in the order of tens of millimeters per hour, and the operation needs to be repeated several times to achieve the desired purity. The key to improving zone smelting efficiency lies in controlling the melting zone, including its width, melt stirring, and the speed and stability of its movement. Consideration must also be given to the pollution of metals by elements like oxygen, nitrogen, and carbon in the air during smelting, necessitating control of the vacuum or inert atmosphere in the regional smelting device.

The Induction Type Electromagnetic Shielding Area Purification Furnace, denoted as the TPF800-I60, employs a meticulous process for purifying high-purity metals such as indium, tin, bismuth, lead, or zinc with a purity of 4N (99.99%) or higher. This furnace conducts a comprehensive purification procedure within its 1000mm quartz tube, featuring a diameter of 60mm. The process involves the controlled application of high-purity argon and a vacuum environment, ensuring optimal conditions for smelting and purification of metal rods placed in a quartz boat.

Powered by a 25KW AC source at 220V and 50/60Hz frequency, the furnace utilizes a sophisticated induction heating mechanism. The quartz tube incorporates five melting zones, allowing for precise temperature gradients during the purification process. Sample handling is executed with a 500mm quartz boat, and gas control is facilitated through a mass flow controller, offering a flow range from 0 to 500SCCM, with high-purity argon as the working gas. The vacuum conditions are achieved using a molecular pump set with water cooling, maintaining the vacuum level at 4.4×10-3Pa.

Temperature control is critical, monitored by a K-type thermocouple, ensuring accuracy within +/-5°C. The furnace's temperature range spans from room temperature to 1000°C, enabling controlled smelting and purification of metals. A compound vacuum gauge ensures precise vacuum measurements. The molecular pump boasts a pumping speed of 600L/s, complemented by the VRD-4 fore pump with a backing pump pumping speed of 1.1L/s. This purification furnace, with its nuanced process and robust technical specifications, serves as an indispensable tool for industries requiring high-purity metals, offering efficiency, precision, and reliability in the purification of indium, tin, bismuth, lead, or zinc.

Disclaimer: The information presented on this website, including product images, product descriptions, and technical parameters, serves as a reference guide. Please note that due to potential delays in updates, discrepancies may exist between the content displayed here and the current product status. We encourage you to reach out to our dedicated sales team to verify the most up-to-date details. It is important to understand that the information provided on this site does not constitute a formal offer or commitment, and our company reserves the right to periodically enhance and amend website information without prior notice. We appreciate your understanding in this regard.