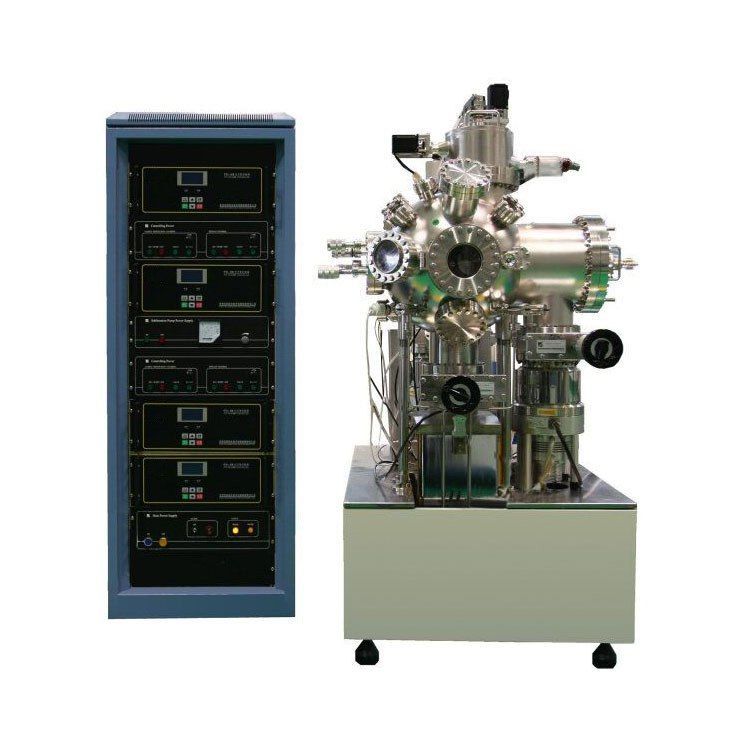

Dual chamber pulse laser coater

Dual chamber pulse laser coater consists of vacuum chamber (main sputtering chamber, sample inlet chamber), sample transfer mechanism, sample frame, rotating target table, vacuum exhaust, vacuum measurement, electrical control, gas distribution, computer control and other parts.

Product Description

Introducing the Dual Chamber Pulse Laser Coater, a cutting-edge system designed for the precision growth of optical crystals, ferroelectrics, ferromagnets, superconductors, and thin film materials comprising organic compounds. This coater proves highly versatile, specifically tailored for the fabrication of intricate layered superlattice thin film materials containing gas elements and is extensively utilized in both research and manufacturing endeavors within academic institutions.

The dual-chamber configuration is thoughtfully crafted, featuring a primary sphere-shaped vacuum system with a diameter of approximately 450mm. Complementing this is a loading sample system characterized by a vertical cylindrical structure with dimensions measuring dia. 150×150mm. The comprehensive vacuum setup encompasses mechanical and molecular pumps, along with valves, servicing both the main vacuum chamber and the loading sample system. Following baking and degassing, the main vacuum system achieves an ultimate pressure of ≤610⁻⁶ Pa, while the loading sample system attains ≤610⁻³ Pa under identical conditions. Impressively, both systems exhibit a swift vacuum recovery time of 20 minutes, swiftly reaching 5x10⁻³ Pa when briefly exposed to the atmosphere and subsequently filled with dry nitrogen.

Central to the coater's capabilities is a rotating target platform adept at hosting targets of up to 60mm in size. Four target materials can be accommodated simultaneously, facilitating seamless target changes through a revolving motion. Each target enjoys independent rotation at variable speeds spanning from 5 to 60 rpm. The substrate heating platform, tailored for 51mm diameter samples, ensures continuous rotation within the 5-60 rpm range. It excels in precise temperature control, offering a maximum heating temperature of 800℃±1℃, adaptable to specific requirements.

The gas circuit system integrates a 1-circuit mass flow controller and a 1-circuit inflation valve, contributing to the coater's operational efficiency. Optional enhancements include a coherent 201 laser device and a 2D scanning mechanical platform designed for two degrees of freedom scanning. The computer control system oversees various functions, including target conversion, target and sample rotation, sample temperature control, laser beam scanning, and more.

In terms of physical dimensions, the main unit occupies an area of 1800 * 1800mm², while the electrical cabinet, comprising one unit, covers a space of 700 * 700mm². This dual chamber pulse laser coater stands as a pinnacle of technological advancement, catering to the diverse and intricate needs of thin film material research and production in academic and industrial settings.

Disclaimer: The information presented on this website, including product images, product descriptions, and technical parameters, serves as a reference guide. Please note that due to potential delays in updates, discrepancies may exist between the content displayed here and the current product status. We encourage you to reach out to our dedicated sales team to verify the most up-to-date details. It is important to understand that the information provided on this site does not constitute a formal offer or commitment, and our company reserves the right to periodically enhance and amend website information without prior notice. We appreciate your understanding in this regard.