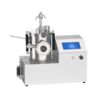

Desktop single-target magnetron sputtering coater with stainless steel cavity

This equipment is a single-target magnetron sputtering coater,it can be used in the preparation of metal film,and also used in electronic fields,optical fields,special field of ceramic preparation ,it surely can be used in SEM sample preparation in laboratory

Product Description

Presenting the MSP190S-1T-A, a desktop single-target magnetron sputtering coater tailored for precise applications, equipped with a high vacuum stainless steel cavity. This cavity, complemented by a quartz observation window baffle, facilitates seamless experiment observation and recording. The compact design with outstanding vacuum performance renders it highly suitable for laboratory settings. To enhance film uniformity and quality, the coater incorporates a rotating heating sample table, combining efficiency with a modular design, simple operational logic, and an intuitive interface for user-friendly initiation.

Operational excellence is ensured within an environment sustaining a temperature range of 25℃±15℃ and a humidity level of 55%Rh±10%Rh. The coater requires an AC220V, 50Hz power supply, duly grounded, featuring a rated power of 1000W. Argon gas purity of ≥99.99% is vital to fill the equipment chamber, with table dimensions measuring 600mm×600mm×700mm and a robust bearing capacity exceeding 50kg. Strategic placement in a well-ventilated and cooled location optimizes its performance.

Technical specifications include a DC power supply with a 300W capacity, delivering a maximum output voltage of 600V and a limited current output of 500mA. The coater employs a 2-inch balanced target with a magnetic coupling baffle, suitable for target materials measuring φ50mm x 3mm in thickness. The cavity, constructed from 304 stainless steel, boasts dimensions of outside diameter 194mm, inside diameter 186mm, and a height of 230mm. The rotating heating sample table allows an adjustable rotation speed of 1~20rpm, reaching a maximum heating temperature of 500℃, with recommended heating rates between 10℃/min and 20℃/min.

Efficient cooling is facilitated through a magnetic target and molecular pump, requiring a circulating water cooler with a 9L tank volume and a flow rate of 10L/min. The gas supply system employs a mass flow meter for argon gas, offering a flow range of 1~30sccm (customizable) and an accuracy of ±1.5% within the measuring range. The vacuum chamber features a KF25 air pumping interface and a 1/4 inch double ferrule joint for air intake. The coater operates through a 7-inch color touch screen, allowing adjustable sputtering current settings, including safety values. Automatic cut-off mechanisms are in place for overcurrent or excessively low vacuum conditions.

Vacuum performance achieves an ultimate vacuum of 5E-4Pa when coupled with a matching molecular pump. Vacuum measurement is facilitated by a Parana vacuum gauge in the range of 1~105Pa. It's crucial to maintain a high-oxygen-free environment, necessitating the cleaning of the vacuum chamber with high-purity inert gas at least three times. The sensitivity of magnetron sputtering to air intake highlights the necessity of a mass flow meter for precise control.

Optional accessories encompass a film thickness monitor with exceptional resolution and accuracy, dependent on process conditions. Supplementary accessories include high-performance molecular pump sets, small molecular pump sets, vacuum bellows, and a film thickness meter crystal oscillator. A stainless steel fine-tuning valve caters to low coating requirements, providing a comprehensive solution for diverse scientific and industrial needs.

Disclaimer: The information presented on this website, including product images, product descriptions, and technical parameters, serves as a reference guide. Please note that due to potential delays in updates, discrepancies may exist between the content displayed here and the current product status. We encourage you to reach out to our dedicated sales team to verify the most up-to-date details. It is important to understand that the information provided on this site does not constitute a formal offer or commitment, and our company reserves the right to periodically enhance and amend website information without prior notice. We appreciate your understanding in this regard.