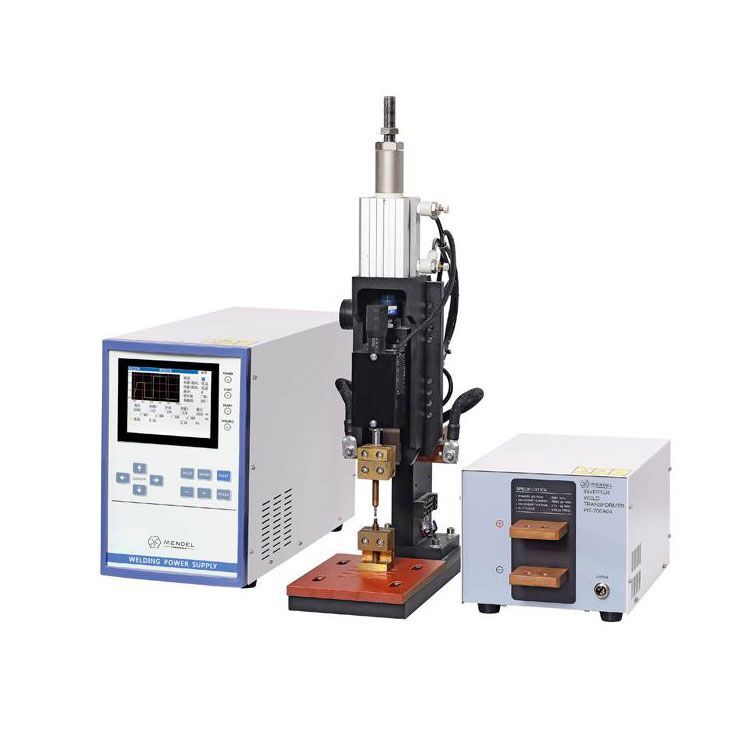

Desk-Top Micro-Computer Control Capacitive Discharge Spot Welder (Electric Pedal Type)

Desk-Top Micro-computer Control Capacitive Discharge Spot Welder (Electric Pedal Type), 208 - 240VAC) - MSK-320B

Product Description

The MSK-320B is a versatile automatic tab welding machine designed for precision and reliability in battery manufacturing. It employs air cooling for efficient operation and features an electrode stroke with an arc welding method. The transmission mechanism is pneumatic, ensuring consistent and controlled welding. This machine is capable of producing multiple welding spots with adjustable welding times ranging from 1 to 99 milliseconds, making it adaptable to various welding requirements. The MSK-320B offers a maximum welding depth of 8.5cm, providing flexibility for different battery configurations. It is backed by a one-year warranty, highlighting its durability and performance reliability. The machine is designed with convenience and accuracy in mind, equipped with a digital LCD controller for precise control and monitoring of the welding process. Specifications include the capability to weld tabs with a thickness ranging from 0.03 to 0.5mm, and it is classified under HS code 85141090. It operates in a portable style, and its electric current is generated through capacitor energy storage, ensuring stable and efficient welding. The welding method is one-sided, and the welding current can be adjusted within the range of 1 to 20A. The machine meets the necessary quality standards and holds CE/TUV certification, ensuring compliance with safety and performance regulations. It is delivered in a wooden box, enhancing its protection during transportation. The MSK-320B represents a cutting-edge solution for precise and efficient tab welding in battery production. The MSK-320B is a state-of-the-art micro-computer-controlled capacitive discharge spot welder designed for precision welding in battery production. Operating at a working voltage of 208-240V AC, 50/60Hz, it delivers a robust output power of 2 KW, with the capability to reach a momentary peak of 10KW when needed. This spot welder offers significant advantages over AC pulse welding methods, ensuring more reliable and consistent welds for high-quality battery manufacturing, including NiMH, NiCd, Li-Ion, LiMnNi, and LifePO4 batteries. One of its standout features is the adjustable welding current, ranging from 0 to 99%, allowing for precise control over the welding process. Additionally, the welding probes are designed for independent pressure adjustment, ensuring uniform welding pressure and eliminating issues such as low voltage or condensation that can occur after welding lithium batteries. The result is a homogeneous welding spot with minimal sparking and no black spots. This spot welder excels in quickly releasing energy for welding highly conductive metals like copper while minimizing heat-affected zones. The MSK-320B is equipped with a built-in optoelectronic welding switch, streamlining operation and eliminating the need to change switches for similar welding tasks. Its digital LCD control panel provides an intuitive interface for parameter configuration, including welding time (adjustable from 1 to 99 ms) and welding current (adjustable from 1 to 20A). The device is suitable for welding tabs with a thickness ranging from 0.03 to 0.5mm, and it includes ten pieces of 0.2mm tabs for customer practice. It offers ample working space, with a maximum opening between the welding tip and the bottom stage of 9cm (expandable to 19cm by removing the bottom stage) and a maximum depth of 8.5cm, measured from the center of the bottom stage to the back end of the machine. The MSK-320B comes with a one-year limited warranty and lifetime support. Its dimensions are 800mm in length, 580mm in width, and 1200mm in height, making it a compact and efficient solution for high-quality battery spot welding.